Core Competence

Sterling Pharma specialises in the development and manufacture of non-sterile oral and topical liquids including semi-solid dosage forms such as creams and ointments. Additional facilities have been provided to manufacture solid dosage forms such as capsules and tablets in small batch sizes.

We offer contract manufacturing services to MAH (Marketing Authorisation Holding) companies for the manufacture of a wide range of pharmaceutical products in a variety of packaging formats.

We have an in-house product development team allowing us to offer product development services for oral liquid products for our customers on a global scale.

Manufacturing Capabilities

Sterling Pharma is one of 1,341 companies that engage in pharmaceutical manufacturing in the United Kingdom, contributing significantly to the development of Life Sciences Sector in the West Midlands and in the whole of the UK.

From inception, the manufacturing activities of Sterling Pharma was initially focused on the preparations of ‘unlicensed’ medicines to cater for those patients whose medical needs were unmet by licensed medications in the UK.

Over the past decade, the company’s steady growth, expansion in operations, international focus, hiring of well qualified and competent employees and significant acquisition of modern machinery have resulted in a remarkable boost to its manufacturing competences, enhancing its ability to offer manufacturing services on a global scale.

Giusti 1,000L process vessel equipped with rotators, contra-rotators and emulsifying mixers

Giusti 500L process vessel equipped with Silverson mixer

Giusti vessels mounted on load cells to enable precision in manufacturing Stand alone Silverson Homogenisor to manufacture from 10L to 100L batches

Greaves Agitator to manufacture up to 200L batches

Air stirrer to manufacture batches up to 200L

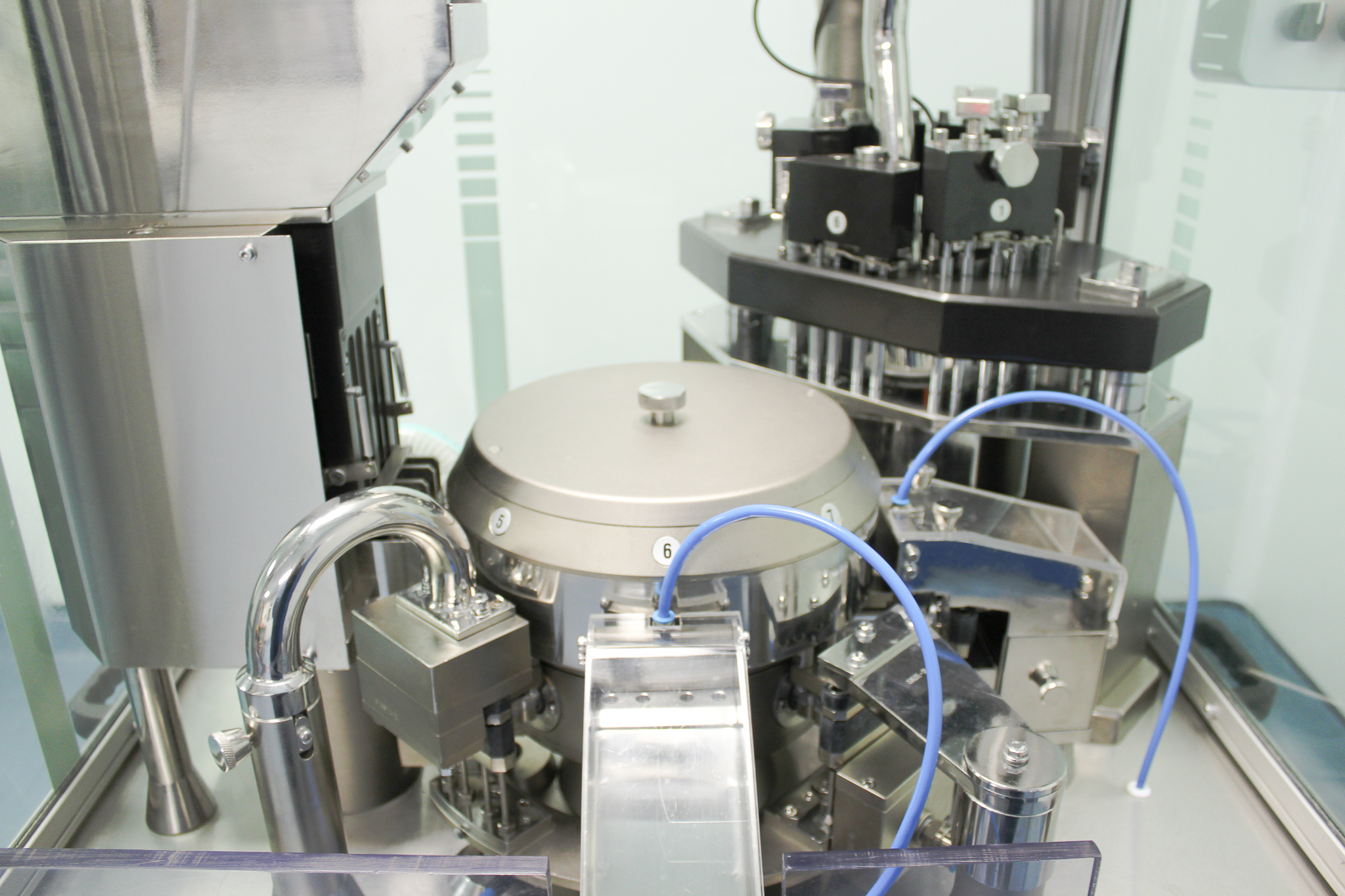

Capsugel CFS 1000 liquid capsule filler

Automatic capsule filler 20,000 capsules per hour

V blenders in various sizes ranging from 1.5L, 20L, 50L and 200L

Automatic liquid filling capping machine to fill glass and plastic containers from 40mL to 500mL

Filling machine for filling small batch runs for smaller container sizes 7.5mL to 30mL

Automatic carton coder to batch code cartons

Sachet filling machine for liquid products

Licensed Manufacturing Facilities

The company’s state of the art manufacturing and testing facilities in Birmingham are licensed by the MHRA, an executive agency of the UK Department of Health.

The company’s manufacturing facility houses a purpose built clean room complex which allows manufacturing and testing of non-sterile liquids and semi-solids in batch sizes ranging from 30mL to 5,000L for liquids and 10g to 50kg for semi-solid products.